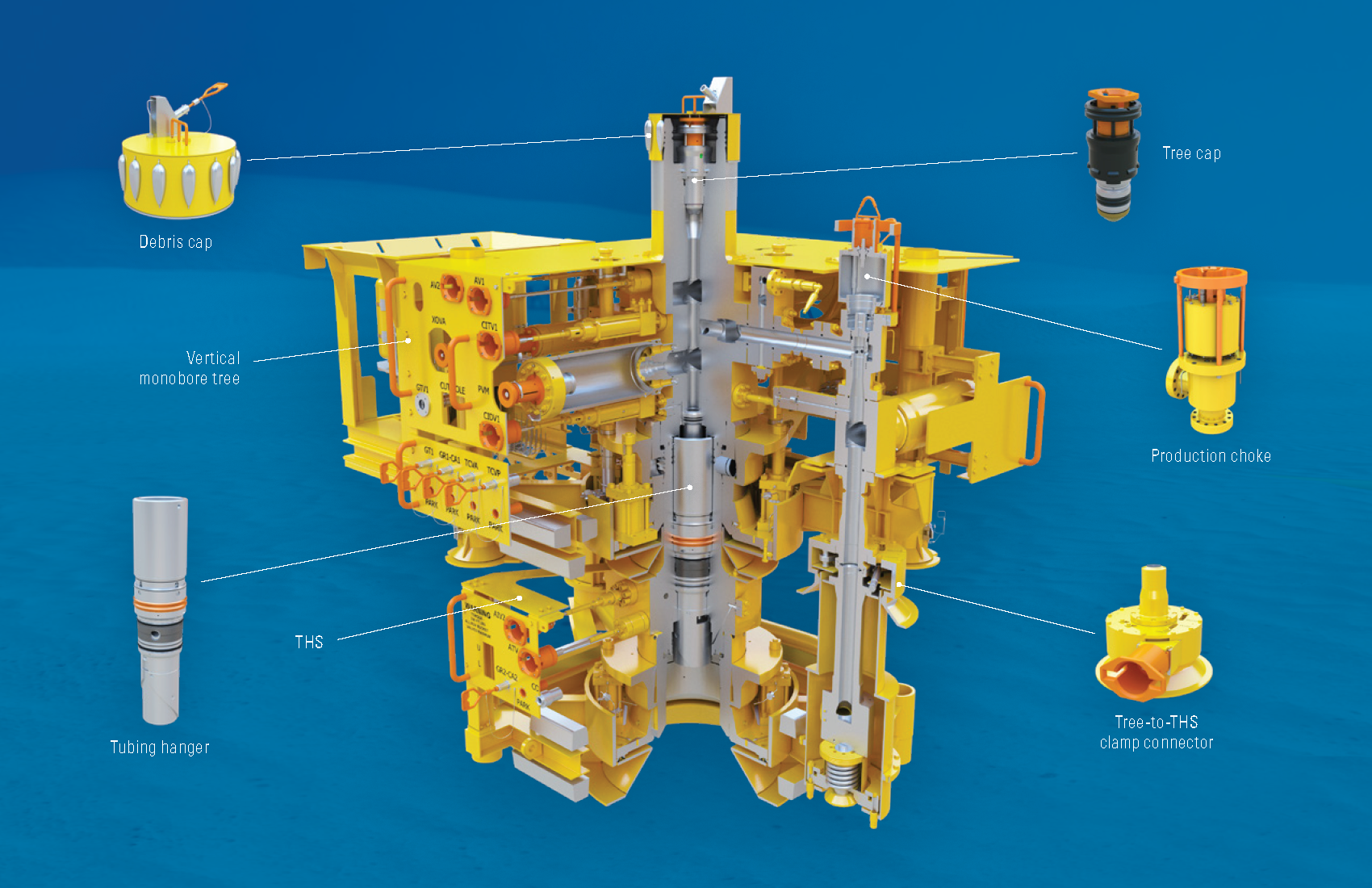

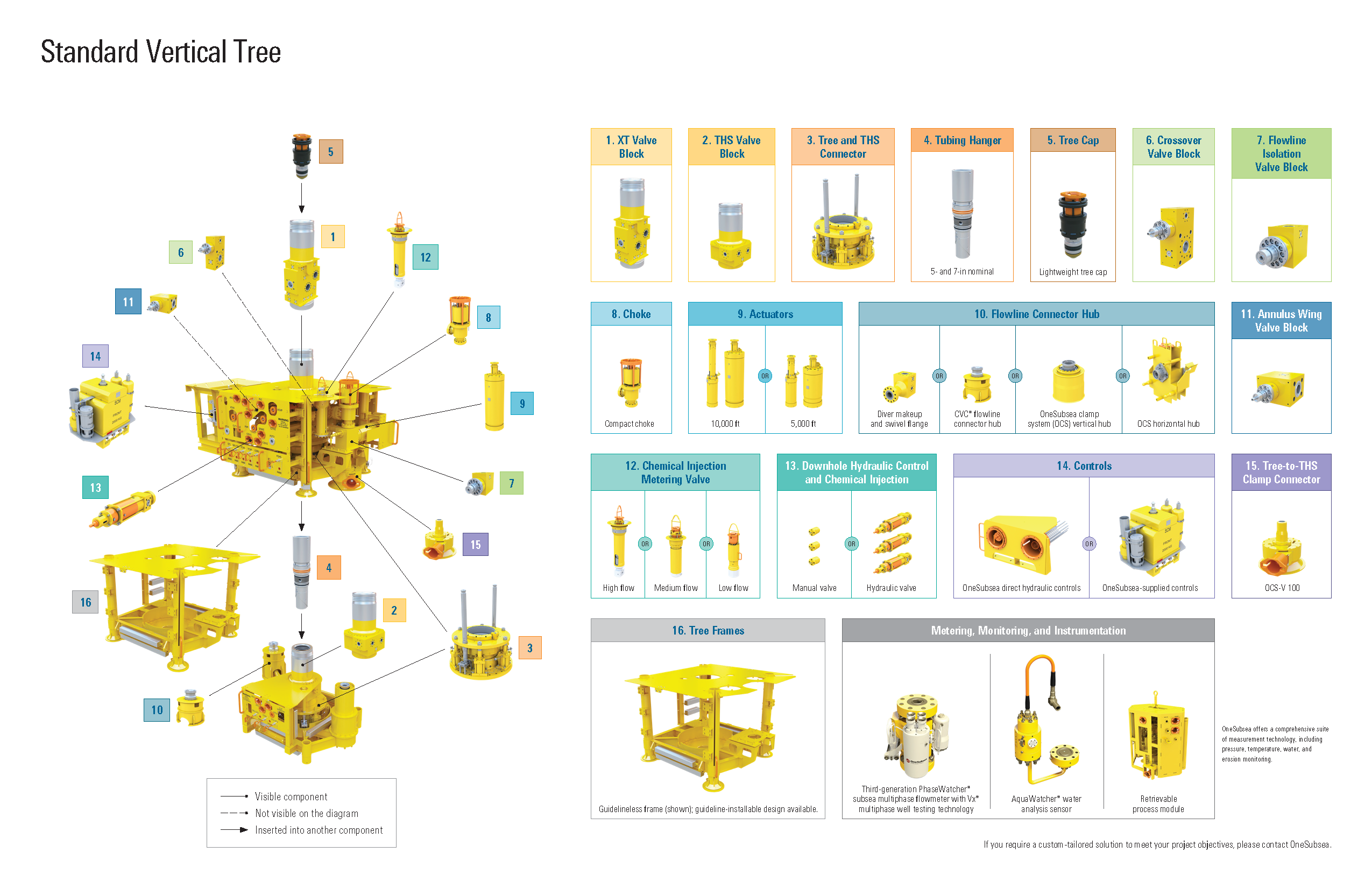

Standard Vertical Subsea Trees

These highly configurable solutions are designed to bring greater efficiency and reliability to subsea operations, enabling project viability and helping you meet a range of functionality requirements while driving down capex

Flexible Functionality

- Common core components, the majority of which are interchangeable with the horizontal tree system

- Ratings of 10,000 psi [689 bar] and 10,000-ft [3,048-m] water depth

- Deployability onto THS

Coating

There is one overall coating procedure comprising two preferred subsea coating systems—one for temperatures up to 122 degF [50 degC] and one high-temperature system for up to 302 degF [150 degC]. The standard coating specification gives the requirements for surface preparation, selection of coating materials, application procedures, and inspection of protective coatings to be applied on the standard vertical tree.

Welding

Our welding procedure for subsea trees conforms to API Spec 6A, ASME Section IX, ASME Code B31.3, and NACE MR0175 / ISO 15156. Adhering to proven, tested, and repeatable processes enables to:

- Standardize welding specifications within and across product lines and vendors

- Provide a superior engineering design that meets or exceeds industry specifications at a lower cost

- Deliver increased value by enhancing the product without incurring added costs.

Quality Control

The QC requirements for the subsea tree are in accordance with API Specifications 6A and 17D. Our facilities are certified per API Spec Q1, and our strategic subcontractors are certified to ISO 9001. Surveillance by independent competent bodies facilitates preengineering of materials, which enables preordering and, in certain cases, stocking them to secure lead time and protect schedule. Surveillance by customers is available during factory-acceptance testing.

Materials

All material specifications used conform to API Specs 6A and 17D and were chosen on a component-by-component basis. Pressure-containing components additionally conform to DNV GL recommended practices (RP) for steel forgings for subsea applications (DNVGL-RP-0034). A range of standardized material options is available based on component criticality, manufacturability, and environmental compatibility.